Air Leakage Testing

Comprehensive Air Leakage Testing for All Building Types

Air leakage testing is an essential part of modern building science, helping owners, designers, and contractors verify energy performance, durability, and occupant comfort. These test methods measures how well a building resists uncontrolled air movement through the envelope. Identifying and addressing leakage early not only improves efficiency but also reduces the risk of moisture problems, drafts, and code compliance issues.

The process often begins with pre-testing of assemblies, mockups, and partial buildings, allowing teams to evaluate performance before full construction is complete. This proactive step identifies weaknesses early, when corrections are easier and more cost-effective. Once the building is ready, whole building airtightness testing is performed to measure leakage across the entire enclosure.

These tests can be conducted on single-zone buildings, multi-zone facilities, and even large buildings exceeding 500,000 square feet, using calibrated blower door systems capable of handling high volumes.

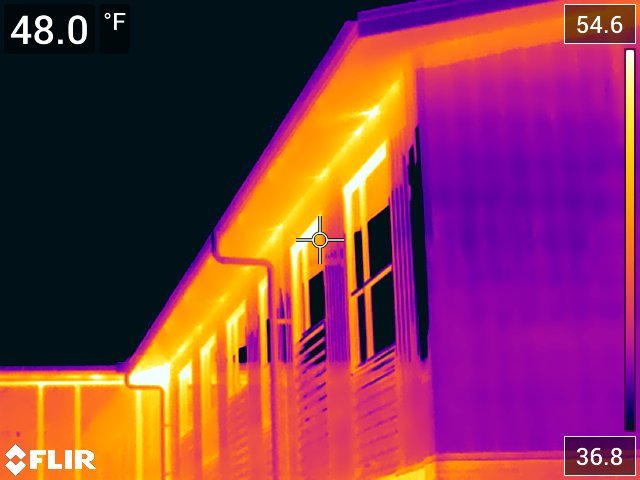

Beyond quantifying leakage, diagnostic testing is used to locate problem areas. Techniques include infrared thermography with IR cameras, which visually capture temperature differences to reveal leaks, and smoke tracer testing, which makes airflow visible in real time. Together, these tools provide valuable insights into how and where a building is losing energy.

Air leakage testing follows established methods to ensure accuracy and consistency. Commonly applied methods include ASTM E1186-22 (air leakage site detection), ASTM E1827-11 and ASTM E779-19 (single- and multi-point blower door tests), ASTM E3158-18 (large building testing), and ASTM E783-03 (window and door air leakage). Each testing method is designed to address specific building types, sizes, and testing objectives.

By combining quantitative testing with diagnostic techniques, air leakage testing provides actionable data that improves building performance, ensures compliance with evolving energy codes, and helps deliver healthier, more efficient spaces.

Frequently Asked Questions About Air Leakage Testing

What is air barrier testing, and why is it important?

Air barrier testing ensures that your building is properly sealed to prevent air leaks that can lead to energy loss, moisture issues, and poor indoor air quality. Air barrier testing is critical to ensuring compliance with local building codes and state energy regulations, helping to create more sustainable and efficient buildings.

How does air barrier testing work?

During air barrier testing, a specialized blower door system is used to either pressurize or depressurize the building. This helps identify leaks and weaknesses in the air barrier system by measuring how much air escapes or enters the building. The results allow for targeted remediation of problem areas, ensuring that the air barrier system performs as intended.

Are air barrier tests required by building codes?

The requirement for air barrier testing is driven by local building codes and energy standards. Many jurisdictions mandate testing, particularly for larger buildings or projects pursuing energy-efficient certifications. Conducting these tests verifies that the building envelope meets performance criteria for energy efficiency, moisture management, and occupant comfort. Because standards can vary, it is important to review the specific regulations in your area to determine when testing is required.

What are the benefits of air barrier testing?

The main benefits of air barrier testing include improved better moisture management and an accurate reading of the building’s performance. Proper air barrier systems also help prevent drafts and water intrusion, leading to a more comfortable and durable building. Additionally, air barrier testing ensures compliance with energy codes, potentially qualifying your project for certifications.

How do I prepare for air barrier testing?

To prepare for air barrier testing, make sure your building is fully enclosed, with windows, doors, and other openings properly installed. It’s also important that all mechanical systems, such as HVAC, are functioning and that any potential obstructions are cleared. Working with an experienced testing agency like QED LAB ensures that the process runs smoothly and efficiently, meeting all local code requirements.

Looking for more information about Building Envelope Testing?

At QED LAB, we offer a Lunch and Learn where we provide valuable insights into code requirements and building envelope testing. Our experts will explain how these tests are performed and meet compliance with building codes. Join us for lunch and learn more about building envelope testing today!